Before PCs were planned, inventive person’s necessities to use whatever resources were open at a chance to make working models of advancements and thing redesigns. Cardboard was a progressive visitor to the universe of construction and elevating and appreciation to PC programming those days are done and rapid tooling PR can make working models on a creation scale. The principle things an individual requirement is induction to a PC that has Computer Aided Design CAD programming presented, and their inventive brain to convey any idea in full concealing and action, with the total of the fundamental assessments to make the essential unit off the creation line. In case you do not move toward a PC, check with your local library and get some data about using their copy of CAD programming.

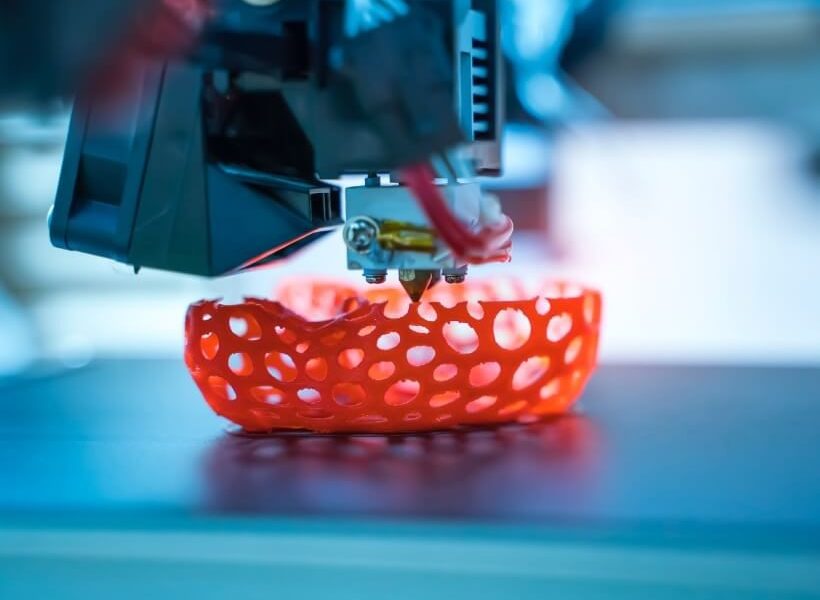

Dependent upon the applications, and the materials used, there are different kinds of RP machines which can be used. All of them may fabricate one part of the completed model, and a short time later the sum of the parts will be gathered. The sum of the assessments from the CAD report is dealt with into the electronic FDM 3D Printing machines and the result is a completed thing that far beats the old thought about a cardboard demo. There have been magnum opuses produced using old focus point tops, nonetheless nothing can appear differently in relation to having the alternative to bring your creation into a PC and have the parts tooled straightforwardly before your eyes. Various people do not comprehend that RP can make a masterpiece from essentially a PC record, and some machine mechanical assemblies. They might be astounded at this sort of 3D craftsmanship.

With such a lot of movements as nanotechnology appearing on the scene, it is as of now possible to pursue things that solitary quick prototyping can achieve. Exactly when lasers are used in the tooling cycle, pitiful layers of material can be eliminated from a segment which is little so much that it requires an incredible amplifying instrument to attempt to find the part. This is an ordinary practice that considers phenomenal worth reductions and helpers in decreasing lead-times. You can shoot most structure grade materials in a speedy device. Using aluminum instruments licenses you to test comparable materials as you would in a creation structure. Glass-filled Nylon, Ultimo, Peek and PVC have all been run in aluminum instruments. These molds can be cooled or warmed to meet the taking care of necessities. The day of simply shooting ABS or Santorin is done. Filled materials, interesting materials and waxes are by and large being tried in aluminum contraptions usually to get valuable models or low-volume creation parts.